Open time

Minimum and maximum time after printing a layer when you can overprint with the next layer without the wall collapsing. This is also very dependent of when the accelerant is added, i.e in the original mix or just before printing, and in what percentage.

Printing speed

For most 3D printable concretes typical printing linear speeds are from 150 – 300 mm/second. You want to keep the print speed constant during a print and not slow down or speed up around corners as this will result in uneven structural properties, as it is a timed chemical process. There are some polymer based cements which can be printed a lot faster.

Minimum Print radius

This is dependent on the maximum acceleration/deceleration achievable with the printer X/Y linear axes. Our larger VSF systems have very high acceleration rates and are able to print with a constant surface speed of 300 mm/sec with a corner radius of 45 mm.

Print Bead width and height

3D printable concrete

with < 3mm aggregate will be extruded with a 40-60mm bead width and 6-12mm

bead thickness. Concrete with larger aggregate will be wider and thicker

depending on the aggregate diameter. Geopolymer cements and high density

geopolymer cements are strong and flexible and so are printed with typically 15-25

mm bead width and 2 to 6 mm thickness, so need less material than conventional

3D printable concretes. The result is very fast print speed and a better

surface finish.

Curing time

Conventional concrete takes typically 24

days to cure. Addition of accelerants and other chemicals can shorten this a lot but may lead to micro

cracking. This is very important when you need to move a printed part after

manufacture.

Compressive and flexural strength

Achieved during

and after curing can be improved by the addition of fibers or larger aggregate.

Ther are many types of concrete for 3D printing but indicative values for well

printed concrete with a density of 2350 kg/m3 are compressive strength of 70–100

MPa, flexural strength of 6–20 MPa depending on testing direction, and tensile

bond strength between layers varying from 2.3 to 0.7 MPa, reducing as the

printing time gap between layers increased.

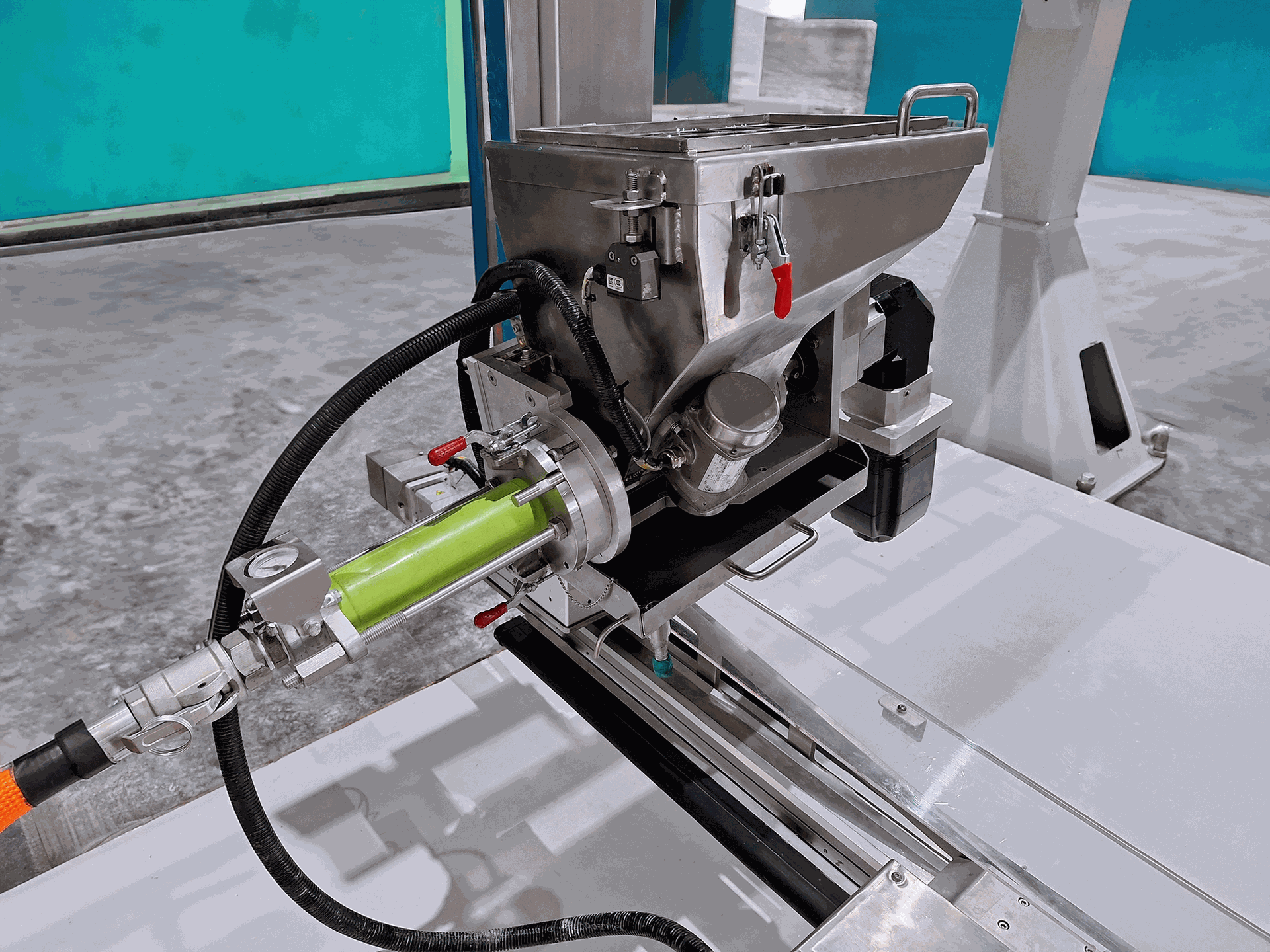

Aggregate size

Most 3D printing systems use aggregate

less than 3mm in diameter as this can be pumped with standard progressive

cavity pumps and forms a smooth surface. For larger aggregate, up to 20 mm diameter,

large pitch augers are required and the surface finish is lumpy.

Fibers

There are many fibers being evaluated for

concrete printing including , steel fibers, polyester, hemp and others. Here it

is important to be able to dispense the fibers in the correct percentage and

mix evenly before printing. Fiber content is generally in the range of 0.1% to

3% by volume.

Environment

Concrete printing and curing is very

dependent on the percentage of water which is strongly influenced by ambient

temperature, humidity and exposure to sunshine and wind. Onsite printing needs

to be covered to prevent rain and sunshine damaging the printed part. A better

result can be achieved with parts pre-fabricated in a factory environment, but

still subject to variations in humidity and temperature.

Material Price and other costs

Concrete is a

major cost for a building and the construction industry is very competitive. Generally,

3D printable concrete is more expensive than standard concrete. However, it has

advantages in speed of manufacture and flexibility in the shapes which can be

produced without formwork. Most concrete is produced locally as it is too heavy

to easily transport. Many universities and concrete companies are investing in

research in 3D concrete materials. We work with several of them.

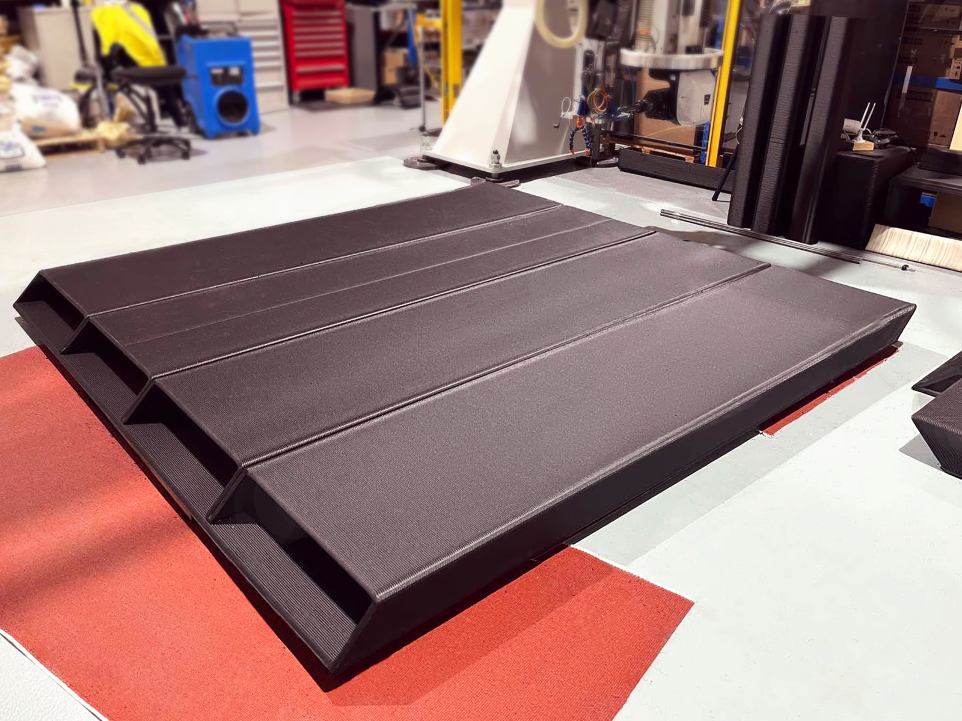

Surface finish

The 3D printing process results in a ribbed surface, with the layer spacing dependent on the print bead thickness and the surface finish depending on the material used, drying times etc. Where a flat surface is required, the printed surface can be rendered or polished. Alternatively smart part programming can be used to create various weaving or other patterns while printing. We have experience also with CNC milling of partially cured concrete and this is an option on some of our VSF systems.

Building Approvals

Construction industry in all countries is required to conform to local building and construction codes. Additive manufacture of buildings is covered under prefabricated construction codes in several countries. Typically, this focuses on consistency of the print process and recording of print data such as temperatures, water content, print speeds etc. Approvals are generally case by case.

Structural Walls

3D printable concrete walls and parts are often non-structural as they contain small aggregate and no steel re-enforcing. A common way to make a wall structural is to print a cavity in the wall and fill this with metal bar and conventional concrete. This is an easy way to make a structural column as the 3D printed wall makes the formwork for this.

Formwork

Printing concrete or thermoplastic formwork has the advantage of flexibility in the shapes to be made. You do not need to get custom formwork. Currently formwork can make up to more than 30% of the cost of a concrete construction. 3D printed and machined thermoplastic formwork is becoming more common for GRC panels as an alternative to timber formwork.

Sustainability

Reducing CO2 emissions is a requirement for all companies, with all countries legislating CO2 reduction targets. Portland Cement is responsible for around 10% of all CO2 production. Many universities and companies are looking at a concrete printing using re-cycled and low CO2 emission materials, such as geopolymer cement as a solution for this.