Our VSF 3D printing technology features a high-performance pellet extruder capable of handling a wide range of different materials.

With super fast printing speeds and accurate process control and monitoring, this system is designed to significantly enhance productivity and reduce production time across various applications and industries.

Our VSF 3D printing technology features a high-performance pellet extruder capable of handling a wide range of different materials.

With super fast printing speeds and accurate process control and monitoring, this system is designed to significantly enhance productivity and reduce production time across various applications and industries.

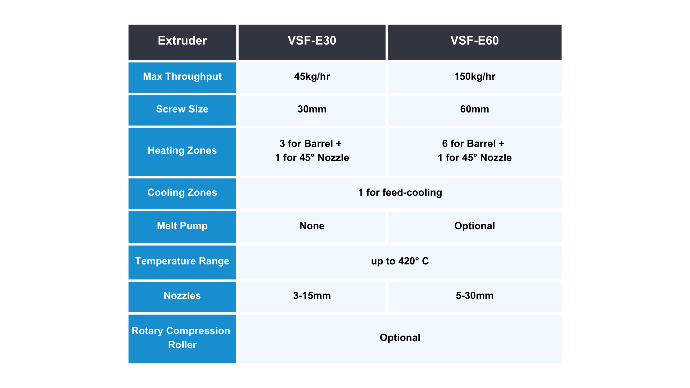

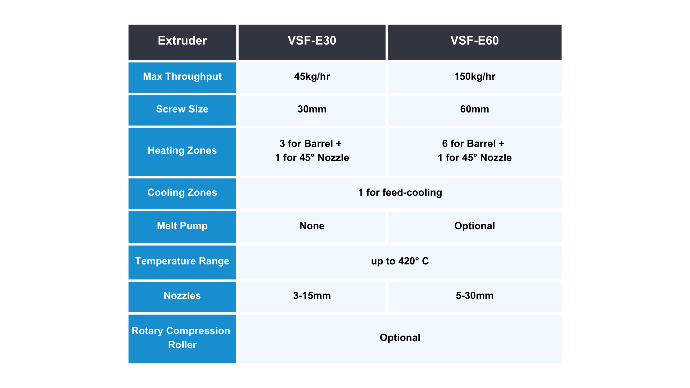

VSF-Extruder

High performance pellet extruder for a wide range of different materials:

- Super-fast print speeds for efficient production

- Perfect for mid-sized to large prints

- Multiple, individually accurately controlled heat zones. Parameters set up based on recipes for a given print strategy and material (see VSF Print Assistant)

- Accurate process control and monitoring for high-quality printing (see VSF Print Cockpit)

- We supply a range of print nozzles with diameters from 3 to 32mm in 90 degree or 45 degree versions.

High performance pellet extruder for a wide range of different materials:

Super-fast print speeds for efficient production

Perfect for mid-sized to large prints

Multiple, individually accurately controlled heat zones. Parameters set up based on recipes for a given print strategy and material (see VSF Print Assistant)

Accurate process control and monitoring for high-quality printing (see VSF Print Cockpit)

We supply a range of print nozzles with diameters from 3 to 32mm in 90 degree or 45 degree versions.

Print types:

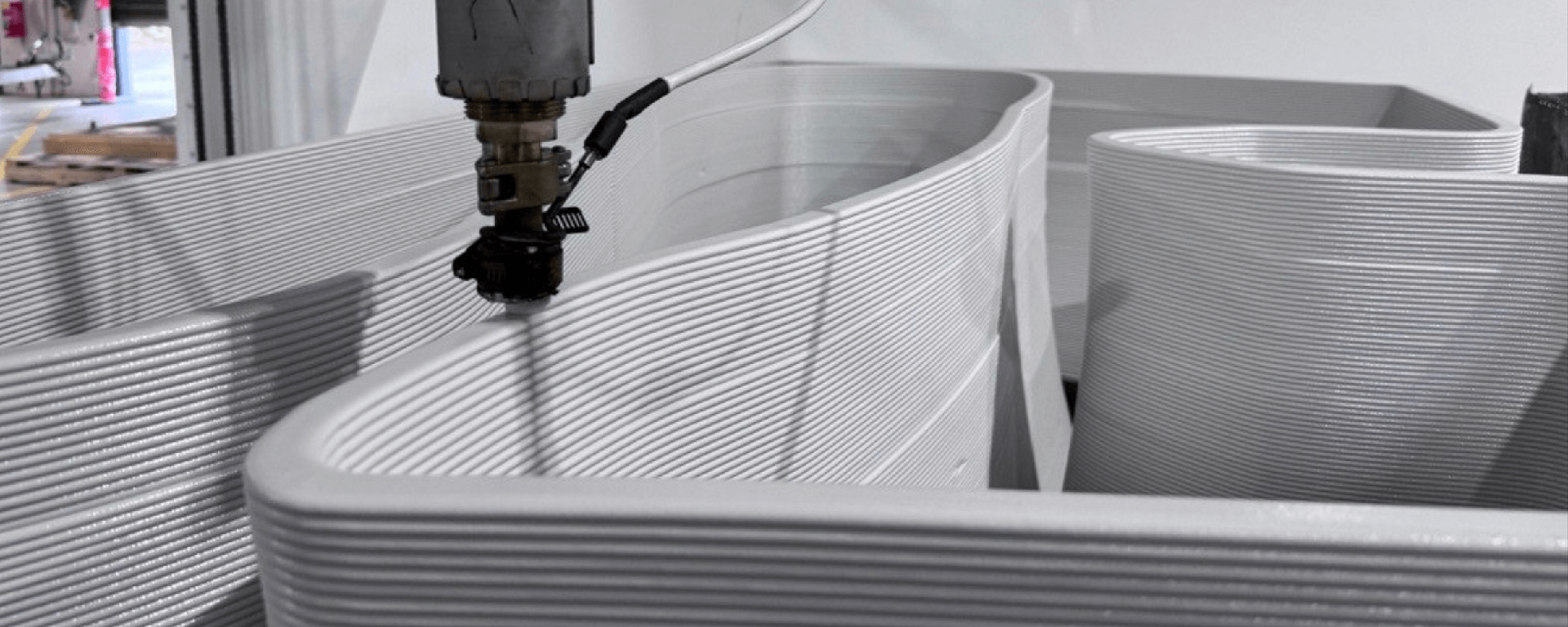

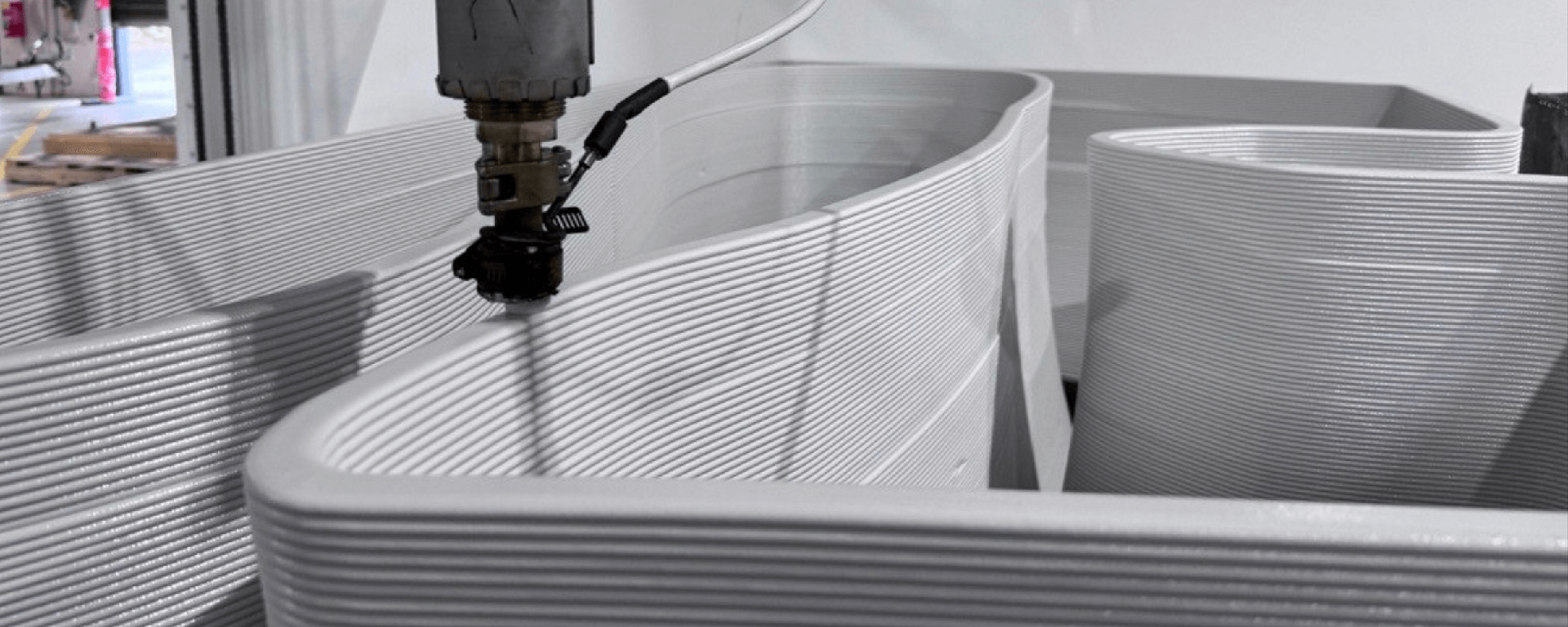

90° Print Nozzle

Vertically printing is suitable for printing parts with single or double walls, and for walls with up to a 30 degree angle from vertical. This uses a straight nozzle. The parts are printed onto a print bed, generally with a printed nest to attach the part to the bed. Part size is limited by the maximum print speed for the wall thickness and the time for the print material to cool between layers.

45° Print Nozzle

45-degree printing is done with a 45 degree nozzle. In this case it is possible to print fully enclosed shapes with ribs or other features inside. This also reduces print path per layer so very large parts can be made. Our thermal imaging system enables the print speed to be calculated and adjusted layer by layer. This is particularly important with these shapes. We print 45 degrees onto a thermal blanket to minimise heat transfer to the bed.

90° Print Nozzle

Vertically printing is suitable for printing parts with single or double walls, and for walls with up to a 30 degree angle from vertical. This uses a straight nozzle. The parts are printed onto a print bed, generally with a printed nest to attach the part to the bed. Part size is limited by the maximum print speed for the wall thickness and the time for the print material to cool between layers.

45° Print Nozzle

45-degree printing is done with a 45 degree nozzle. In this case it is possible to print fully enclosed shapes with ribs or other features inside. This also reduces print path per layer so very large parts can be made. Our thermal imaging system enables the print speed to be calculated and adjusted layer by layer. This is particularly important with these shapes. We print 45 degrees onto a thermal blanket to minimise heat transfer to the bed.

Want to know more?

Want to know more?