The design of VSF 3D Software Tools are based on the principles:

- Ease of Use - best user experience, eliminate operator errors

- First Time Right - Identify and eliminate problems prior to print

- Minimise Waste of Time, Energy, and Material

Guaranteed Quality - Predictable and Repeatable Prints, Process Monitoring and Quality Assurance and easy to master Workflow from Design to Production

The design of VSF 3D Software Tools are based on the principles:

Ease of Use - best user experience, eliminate operator errors

First Time Right - Identify and eliminate problems prior to print

Minimise Waste of Time, Energy, and Material

Guaranteed Quality - Predictable and Repeatable Prints, Process Monitoring and Quality Assurance and easy to master Workflow from Design to Production.

Large scale 3D printing is a complex technology that requires many process parameters to play together accurately to guarantee high quality prints. Drawing from years of expertise, we've crafted VSF Recipes, which are sets of proven process parameters. VSF Recipes are seamlessly integrated into our user-friendly SW Tools supporting your workflow from Design to Print for ease of use.

The use of VSF Recipes reduces complexity and leads to high-quality prints at ease.

VSF Recipes are an open platform and allow modification by the user. This ensures you have a dedicated location to save your constantly growing experience.

Large scale 3D printing is a complex technology that requires many process parameters to play together accurately to guarantee high quality prints. Drawing from years of expertise, we've crafted VSF Recipes, which are sets of proven process parameters. VSF Recipes are seamlessly integrated into our user-friendly SW Tools supporting your workflow from Design to Print for ease of use.

The use of VSF Recipes reduces complexity and leads to high-quality prints at ease.

VSF Recipes are an open platform and allow modification by the user. This ensures you have a dedicated location to save your constantly growing experience.

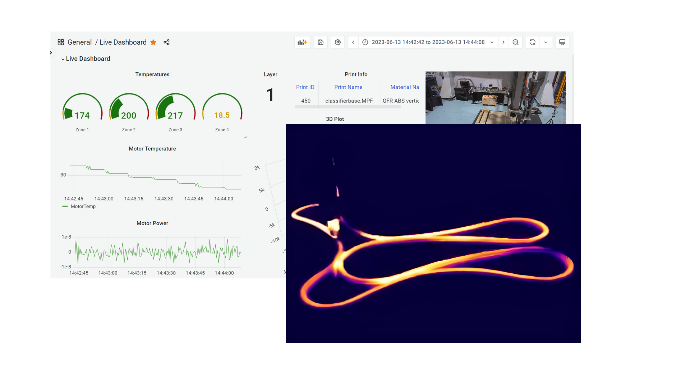

Process Monitoring & Data

Logging & Adaptive Print

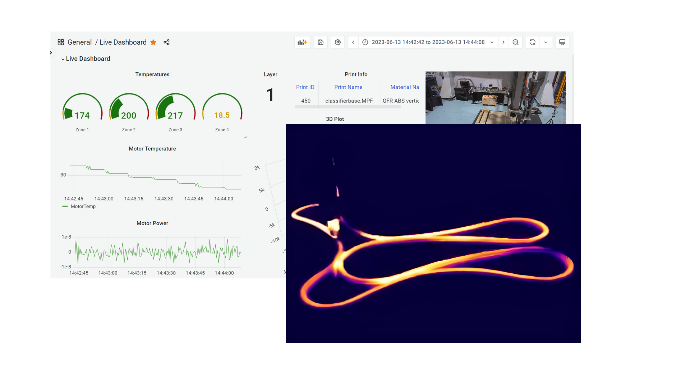

Industry 4.0 Data logging. All print data variables are continually logged during the print process. This data can be used for recorded for quality purposes and to enable analysis of each printed part.

VSF Print Cockpit is a web-based live dashboard of relevant process parameters including the integration of web-cams, thermal imaging, extruder temperature profiles and print feedrate.

Adaptive Printing: Measures and uses the part surface temperature data to automatically adjust print process parameters such as extruder temperatures and print-speed to ensure optimal print quality. It enables unmanned operation without the need for constant remote monitoring. This is useful for printing of large parts which take longer than one shift.

Industry 4.0 Data logging. All print data variables are continually logged during the print process. This data can be used for recorded for quality purposes and to enable analysis of each printed part.

VSF Print Cockpit is a web-based live dashboard of relevant process parameters including the integration of web-cams, thermal imaging, extruder temperature profiles and print feedrate.

Adaptive Printing: Measures and uses the part surface temperature data to automatically adjust print process parameters such as extruder temperatures and print-speed to ensure optimal print quality. It enables unmanned operation without the need for constant remote monitoring. This is useful for printing of large parts which take longer than one shift.

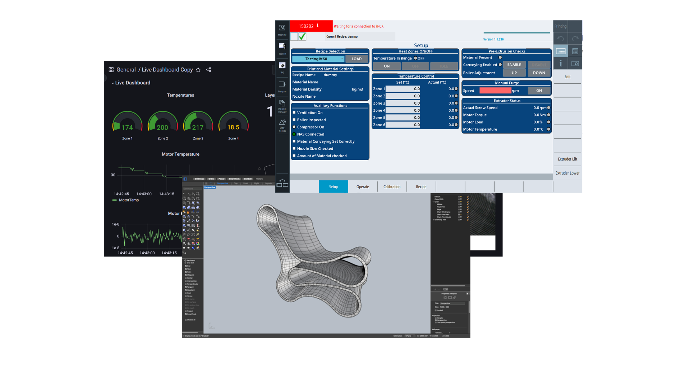

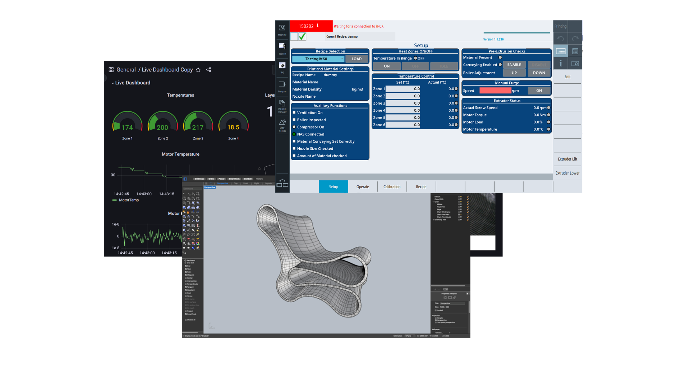

VSF Print Assistant

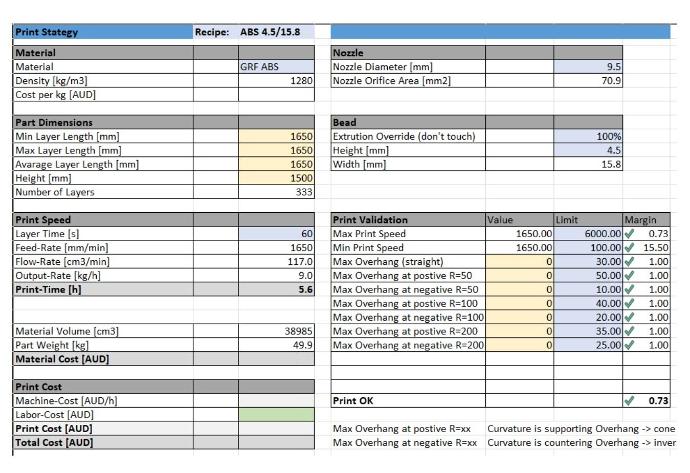

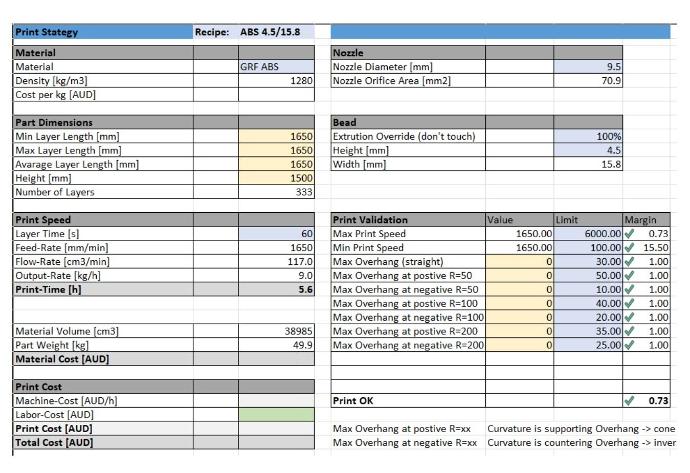

Given a CAD model, the VSF Print Assistant performs a quick pre-print assessment of parameters relevant to your print.

The assessment includes: Printing Time, Material Usage, Feasibility of the Print and Cost estimate based on print time and material usage

The assessment is performed based on a chosen VSF Recipe. The later use of this recipe for the setup of the VSF printer guarantees that printing is executed according to pre-print optimization and at the best achievable quality.

VSF Print Assistant

Given a CAD model, the VSF Print Assistant performs a quick pre-print assessment of parameters relevant to your print.

The assessment includes: Printing Time, Material Usage, Feasibility of the Print and Cost estimate based on print time and material usage

The assessment is performed based on a chosen VSF Recipe. The later use of this recipe for the setup of the VSF printer guarantees that printing is executed according to pre-print optimization and at the best achievable quality.

Want to know more?