Concrete Smart Hose Handling system

Concrete hoses are used for conveying the concrete from the floor mounted mixer/pump to the intermediate tank on the print head. These hoses can be quite long and heavy and manual management is labour intensive.

CNC Design smart hose management system automates the feeding of the concrete hose to keep it above the part while printing but accessible for cleaning or replacement. This has two pairs of servo driven rollers to grip the hose and a catenary system to store the hose. Reeling in and out is synchronised by the CNC Control which know the Print head position at any time and calculates the hose length required. This is available for hoses from 32mm to 80 mm diameter.

Concrete Smart Hose Handling system

Concrete hoses are used for conveying the concrete from the floor mounted mixer/pump to the intermediate tank on the print head. These hoses can be quite long and heavy and manual management is labour intensive.

CNC Design smart hose management system automates the feeding of the concrete hose to keep it above the part while printing but accessible for cleaning or replacement. This has two pairs of servo driven rollers to grip the hose and a catenary system to store the hose. Reeling in and out is synchronised by the CNC Control which know the Print head position at any time and calculates the hose length required. This is available for hoses from 32mm to 80 mm diameter.

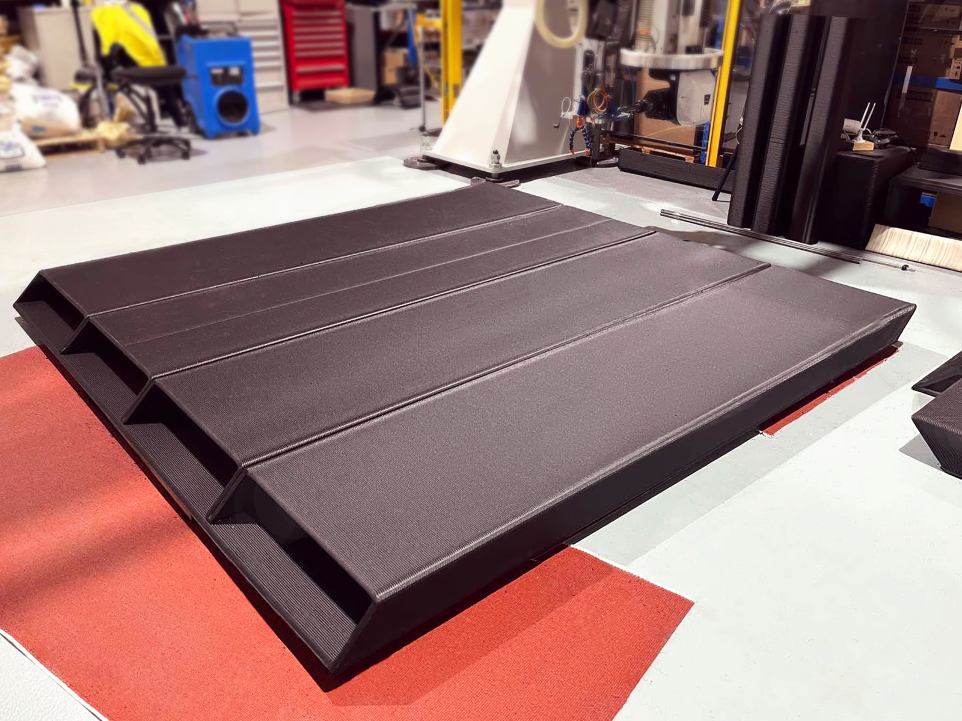

VSF Tool Racks for Concrete 3D Printers

Tool racks for concrete 3D printers play a vital role in enhancing the versatility and efficiency of large-scale printing. These racks enable automatic switching between various print heads and tools, such as different nozzles or milling heads, allowing the printer to handle both the additive and finishing processes without manual intervention.

Key features include:

- Heavy-duty design to support the weight of concrete-specific tools, such as large print nozzles and milling attachments.

- Automatic tool changing, ensuring a smooth transition between printing and surface finishing tasks.

- Precision locking mechanisms to ensure the new tool is correctly aligned for large-scale, accurate concrete structures.

- Durability to withstand the rugged environment of construction sites.

By integrating a tool rack, concrete 3D printers can efficiently manage multi-stage processes, from printing large architectural elements to milling precise details, increasing productivity and reducing project timelines.

VSF Tool Racks for Concrete 3D Printers

Tool racks for concrete 3D printers play a vital role in enhancing the versatility and efficiency of large-scale printing. These racks enable automatic switching between various print heads and tools, such as different nozzles or milling heads, allowing the printer to handle both the additive and finishing processes without manual intervention.

Key features include:

Heavy-duty design to support the weight of concrete-specific tools, such as large print nozzles and milling attachments.

Automatic tool changing, ensuring a smooth transition between printing and surface finishing tasks.

Precision locking mechanisms to ensure the new tool is correctly aligned for large-scale, accurate concrete structures.

Durability to withstand the rugged environment of construction sites.

By integrating a tool rack, concrete 3D printers can efficiently manage multi-stage processes, from printing large architectural elements to milling precise details, increasing productivity and reducing project timelines.

Want to know more?