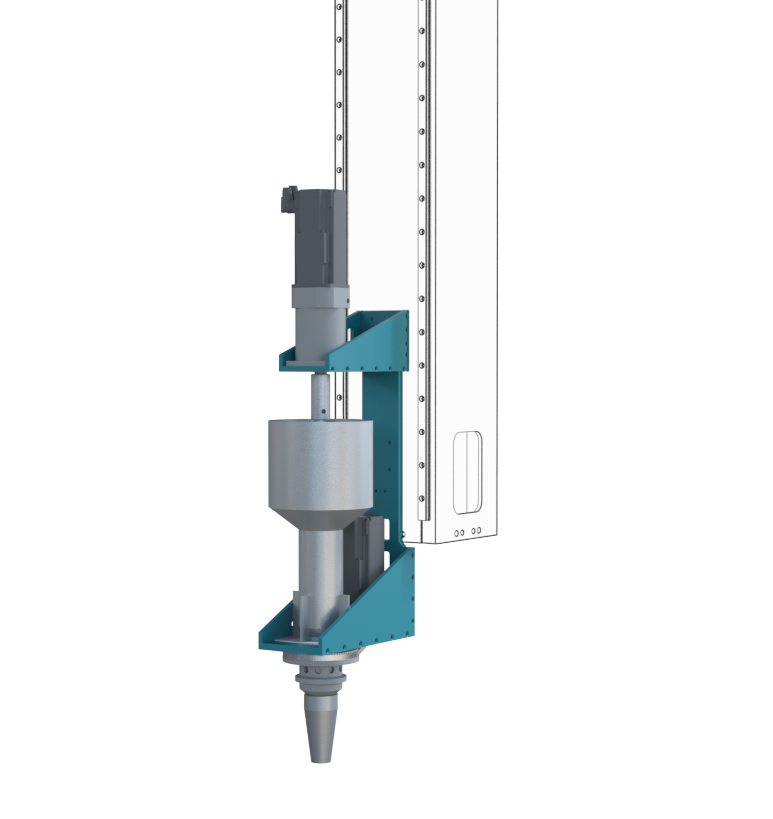

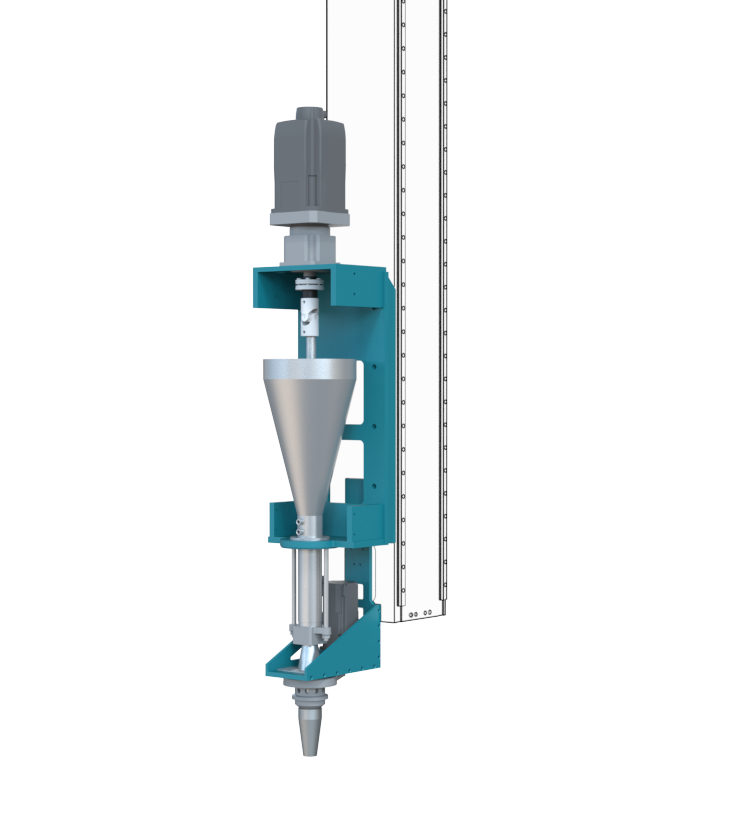

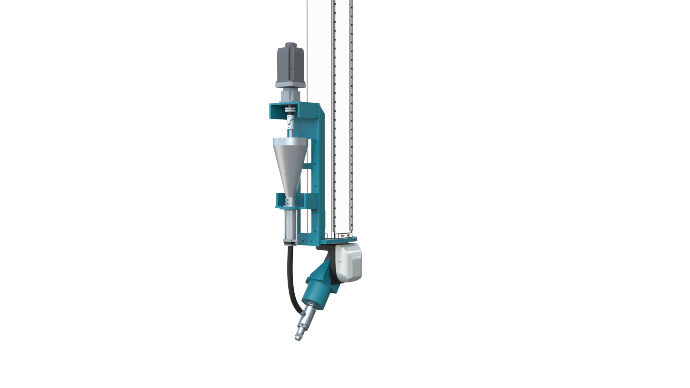

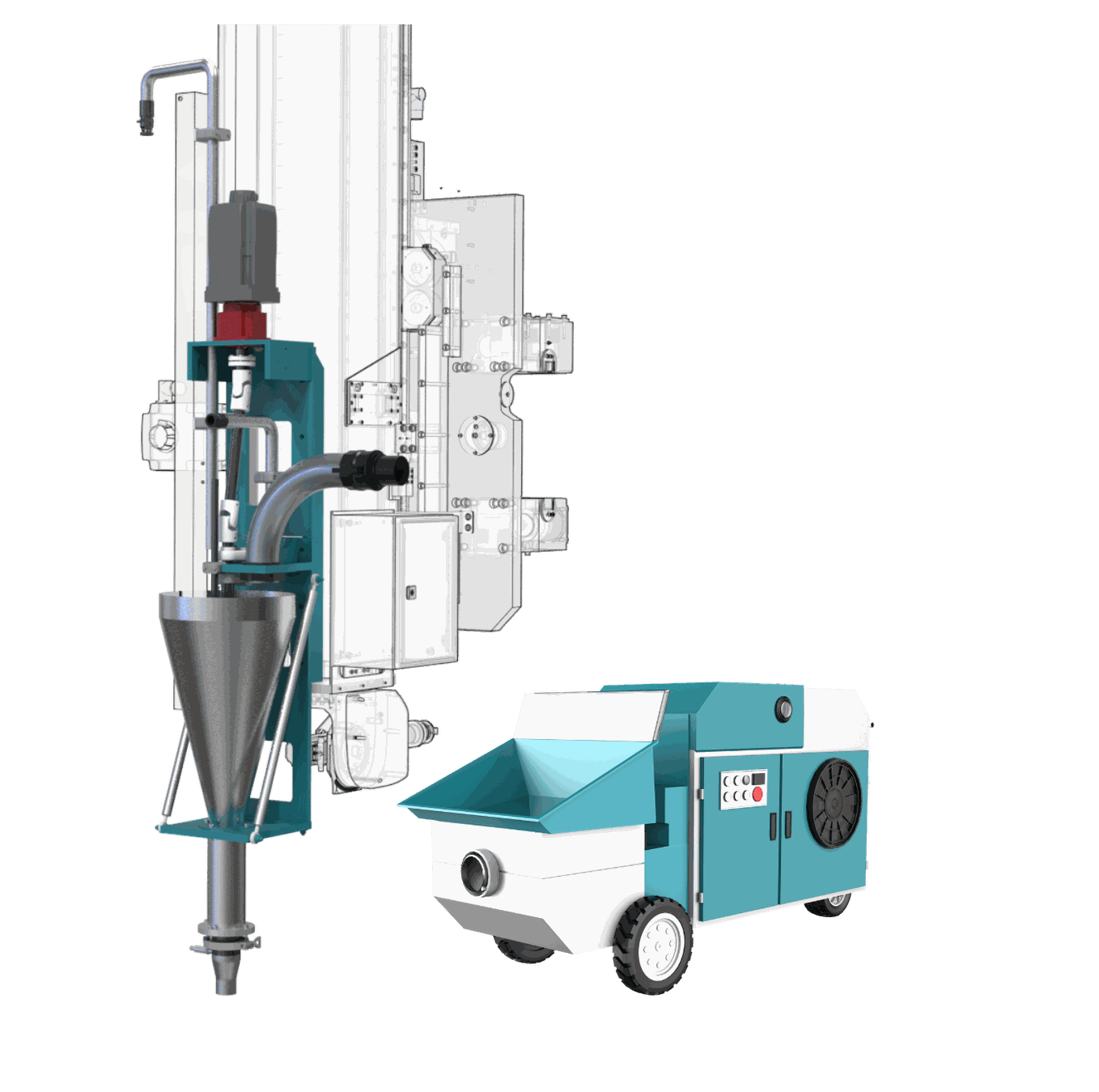

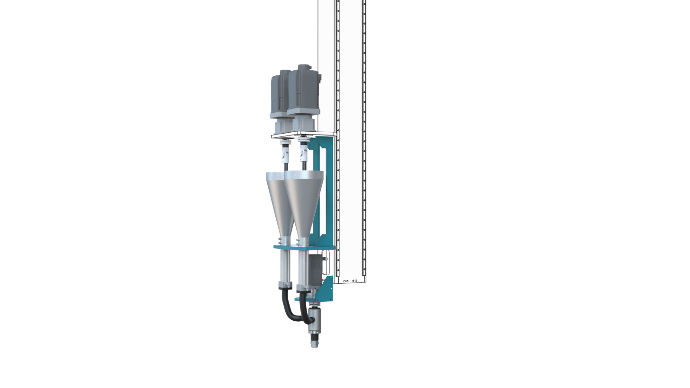

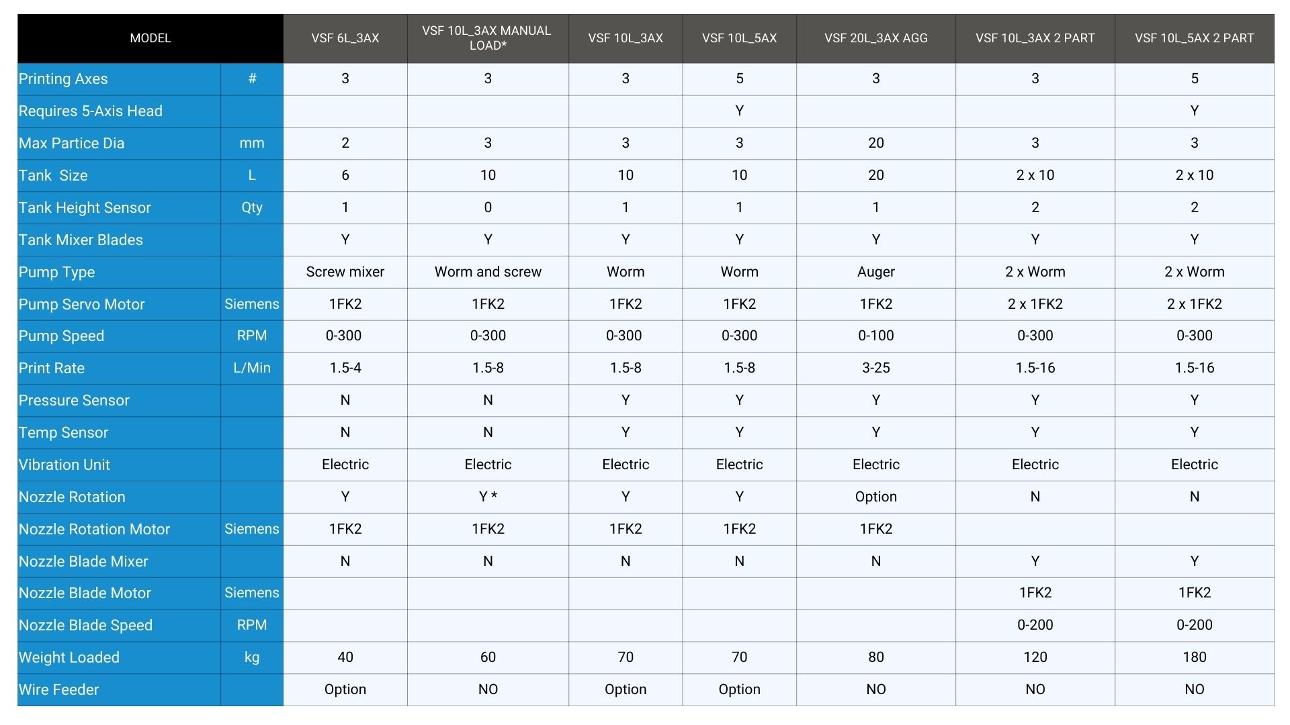

We offer a wide range of VSF Concrete print heads, mixers and nozzle rotation units to suit your 3DCP application. All units are made of stainless steel and are designed for easy disassembly and cleaning. Pumps and nozzle rotation units are driven by Siemens AC servo motors for high dynamic performance.

Our VSF Concrete print heads have the following features:

Integrated intermediate tank(s), designed to be fed from floor mounted material supply systems

Height sensing for intermediate tank which can be linked to the starting and stopping of the floor mounted pump.

Pressure Sensor to monitor pump pressure and prevent pump and hose damage.

Temperature sensor to monitor material temperature

Vibration unit to help remove air bubbles and prevent material sticking to tank walls.

Servo motor and gearbox driven pumping unit with either worm, screw or auger to control material flow.

AC servo motor driven nozzle rotation unit with replaceable nozzles.

Versions are available for 3 or 5 axis printing.

* Manual Loading Mortar Printer 10L-3Ax has horizontal mounted pump with auger feed coupled to a mechanical tank mixer. Nozzle rotation unit is supplied for separate mounting.

We offer a wide range of VSF Concrete print heads, mixers and nozzle rotation units to suit your 3DCP application. All units are made of stainless steel and are designed for easy disassembly and cleaning. Pumps and nozzle rotation units are driven by Siemens AC servo motors for high dynamic performance.

Our VSF Concrete print heads have the following features:

Integrated intermediate tank(s), designed to be fed from floor mounted material supply systems

Height sensing for intermediate tank which can be linked to the starting and stopping of the floor mounted pump.

Pressure Sensor to monitor pump pressure and prevent pump and hose damage.

Temperature sensor to monitor material temperature

Vibration unit to help remove air bubbles and prevent material sticking to tank walls.

Servo motor and gearbox driven pumping unit with either worm, screw or auger to control material flow.

AC servo motor driven nozzle rotation unit with replaceable nozzles.

Versions are available for 3 or 5 axis printing.

* Manual Loading Mortar Printer 10L-3Ax has horizontal mounted pump with auger feed coupled to a mechanical tank mixer. Nozzle rotation unit is supplied for separate mounting.

VSF Concrete 3D Print Heads

When used with VSF systems, our print head pumps , mixers, nozzle rotation and blade rotation speeds are programmable, and can be synchronised with the printing feedrate.

Our Nozzle Blade mixer is designed to provide high shear and mixing of two component cement materials just before printing. It incorporates adjustable angle replaceable blade inserts and is drive by an AC servo motor and gearbox. Application examples can include mixing of geopolymer cements or high density cement materials which are delivered in two parts and then combined and printed.

When used with VSF systems, our print head pumps , mixers, nozzle rotation and blade rotation speeds are programmable, and can be synchronised with the printing feedrate.

Our Nozzle Blade mixer is designed to provide high shear and mixing of two component cement materials just before printing. It incorporates adjustable angle replaceable blade inserts and is drive by an AC servo motor and gearbox. Application examples can include mixing of geopolymer cements or high density cement materials which are delivered in two parts and then combined and printed.

VSF

Cement Print Heads

Print Heads

for 3D Printing with Concrete and Two Components Print Heads

Print Heads

for 3D Printing with Concrete and Two Components Print Heads

The Print Head and printing system are fully modular, making them ideal for high-production environments.

This system can be installed on a single-bridge 3D gantry printer, which is designed for both 3-axis and 5-axis concrete printing. Additionally, the print nozzle can be easily removed and replaced with a milling spindle, offering flexibility for a variety of applications.

The Print Head and printing system are fully modular, making them ideal for high-production environments.

This system can be installed on a single-bridge 3D gantry printer, which is designed for both 3-axis and 5-axis concrete printing. Additionally, the print nozzle can be easily removed and replaced with a milling spindle, offering flexibility for a variety of applications.

Want to know more?