VSF Digital Twin

Digitalisation of the manufacturing process is at the heart of our VSF systems (Virtual Smart Factory) giving you Industry 4.0 performance.

Siemens SINUMERIK Digital Twin technology, offers a cutting-edge solution by harnessing the power of digitalisation and simulation to boost manufacturing productivity and effectiveness. It fully supports part program simulation, evaluation, and refinement, in addition to providing operator training on a virtual platform.

VSF Digital Twin

Digitalisation of the manufacturing process is at the heart of our VSF systems (Virtual Smart Factory) giving you Industry 4.0 performance.

Siemens SINUMERIK Digital Twin technology, offers a cutting-edge solution by harnessing the power of digitalisation and simulation to boost manufacturing productivity and effectiveness. It fully supports part program simulation, evaluation, and refinement, in addition to providing operator training on a virtual platform.

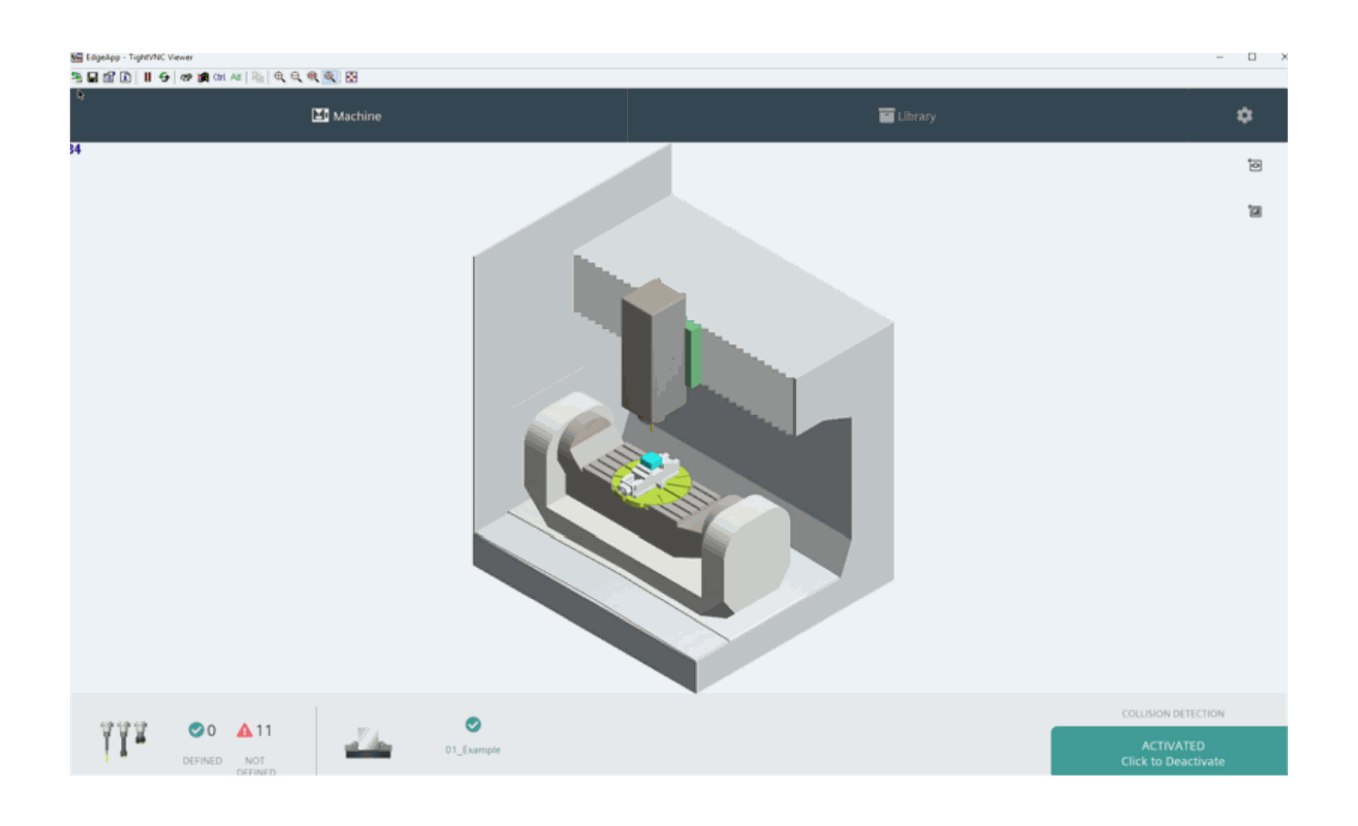

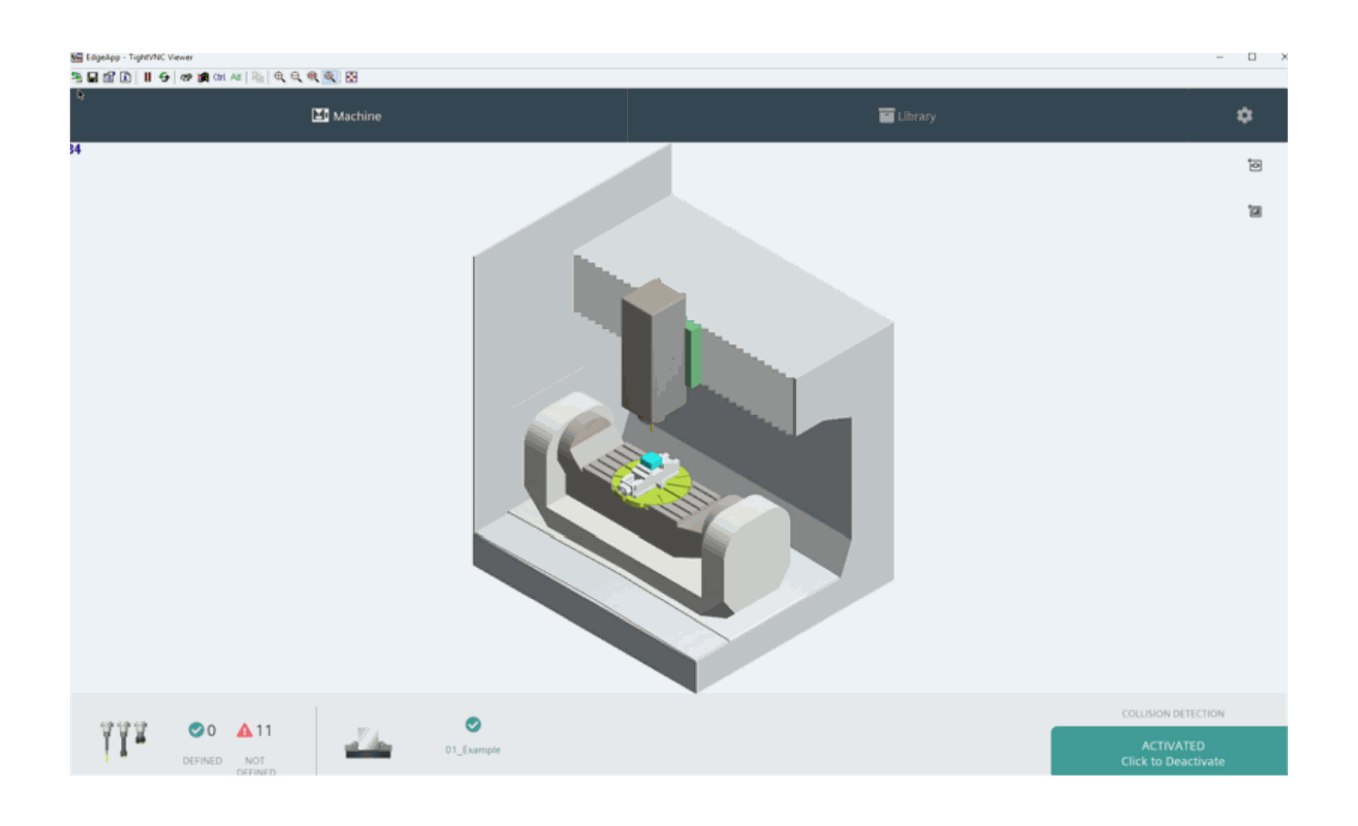

Collision Avoidance - Protect MyMachine

Collision Avoidance - Protect MyMachine

OUR VSF Composite systems are ideal for 5-Axis milling of large parts and moulds, such as those used in aerospace or boat building industries.

We offer SINUMERIK ONE ‘Protect MyMachine’ as an option to help prevent collisions with parts, fixtures and machine elements such as spindles and tooling. Several versions are available depending on your production process. This is real time monitoring on your machine which works in automatic, MDI and jog modes.

OUR VSF Composite systems are ideal for 5-Axis milling of large parts and moulds, such as those used in aerospace or boat building industries.

We offer SINUMERIK ONE ‘Protect MyMachine’ as an option to help prevent collisions with parts, fixtures and machine elements such as spindles and tooling. Several versions are available depending on your production process. This is real time monitoring on your machine which works in automatic, MDI and jog modes.

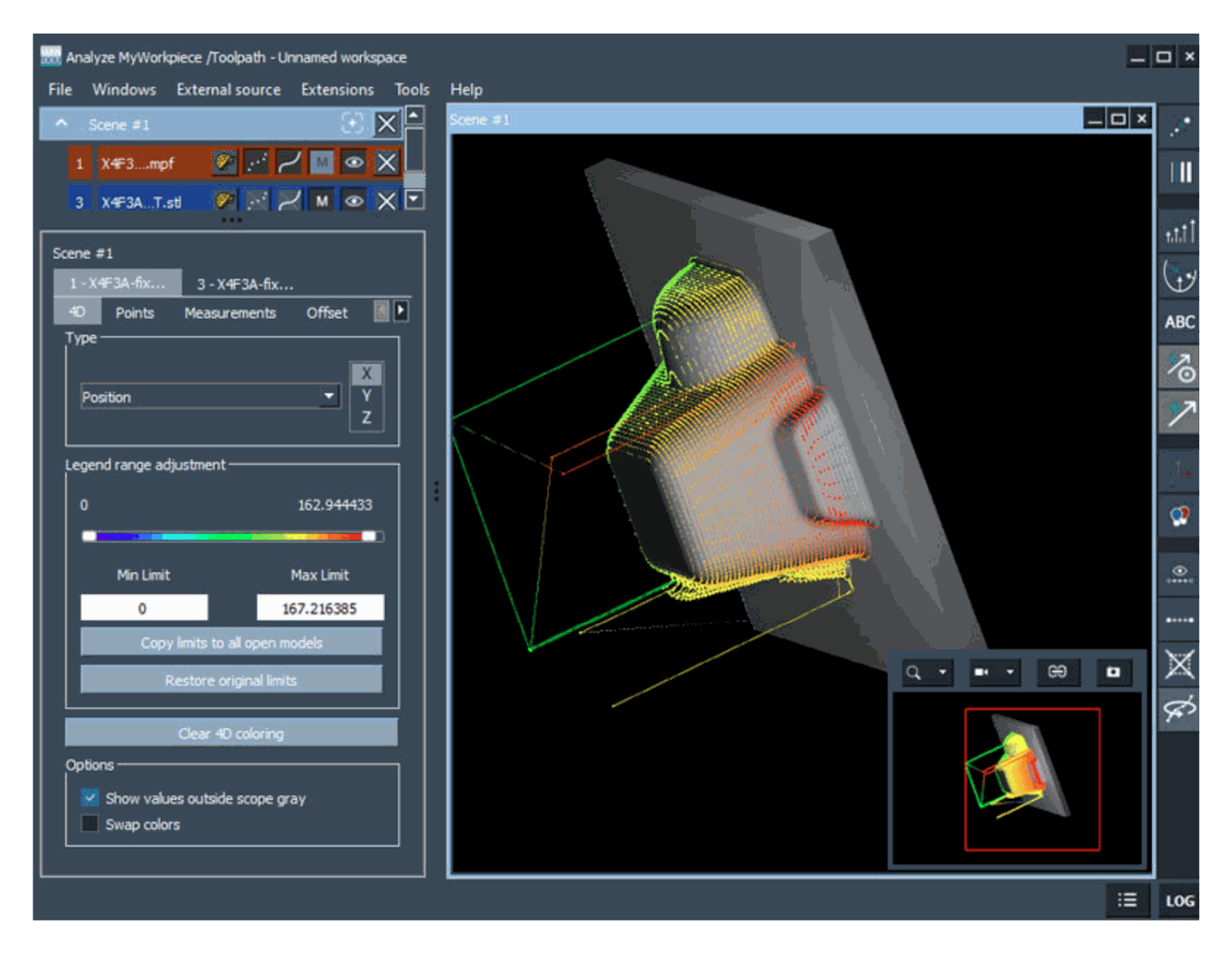

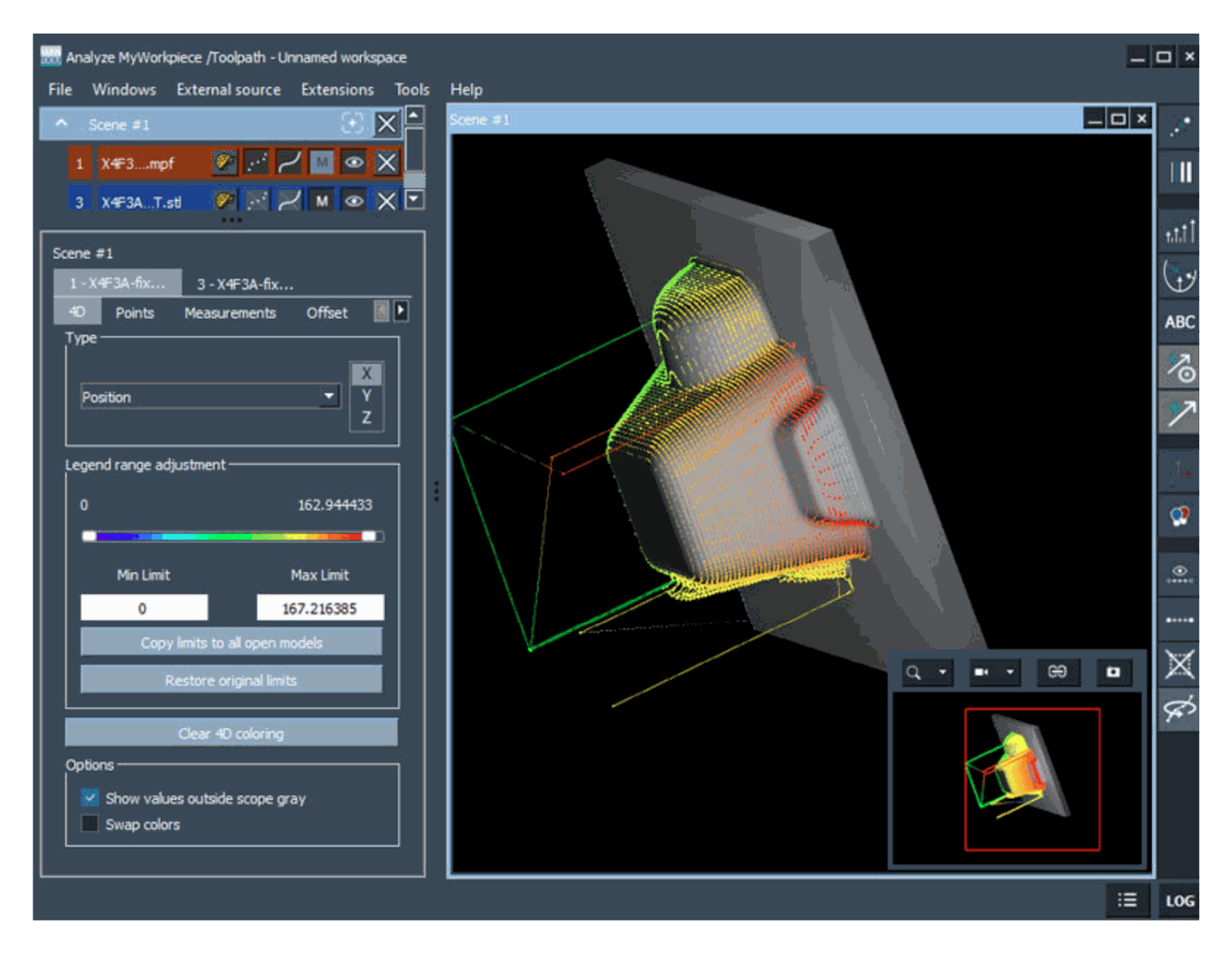

Analyse MyWorkpiece Toolpath

Analyse MyWorkpiece Toolpath

Large 5-Axis parts are expensive and SINUMERIK “Analyze MyWorkpiece /Toolpath” PC tool enables a systematic search for the causes of quality defects in freeform surfaces before you machine a part. Visualisation tools enable you to see the actual surface milling speed at every point on the machined surface. This guarantees quality assurance, even before the first machining trial.

Large 5-Axis parts are expensive and SINUMERIK “Analyze MyWorkpiece /Toolpath” PC tool enables a systematic search for the causes of quality defects in freeform surfaces before you machine a part. Visualisation tools enable you to see the actual surface milling speed at every point on the machined surface. This guarantees quality assurance, even before the first machining trial.

Digitalisation of the manufacturing process is at the heart of our VSF systems (Virtual Smart Factory) giving you Industry 4.0 performance.

Digitalisation of the manufacturing process is at the heart of our VSF systems (Virtual Smart Factory) giving you Industry 4.0 performance.

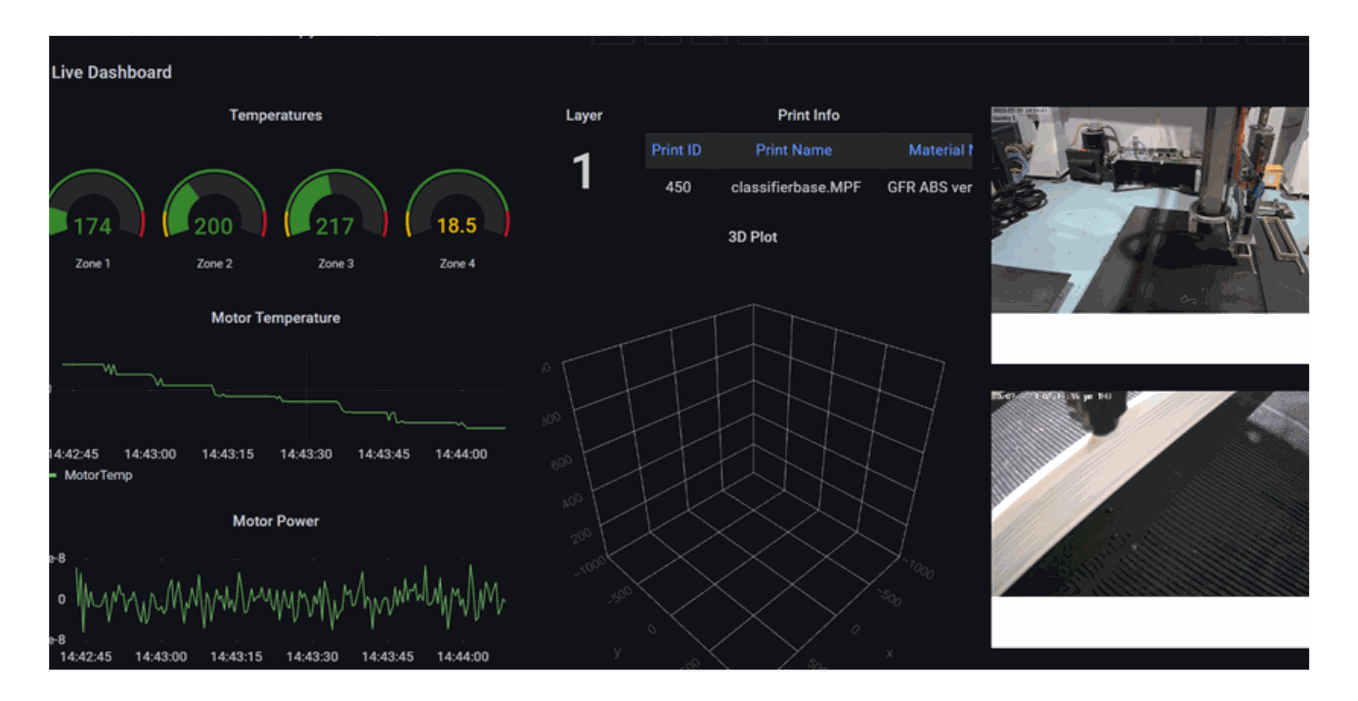

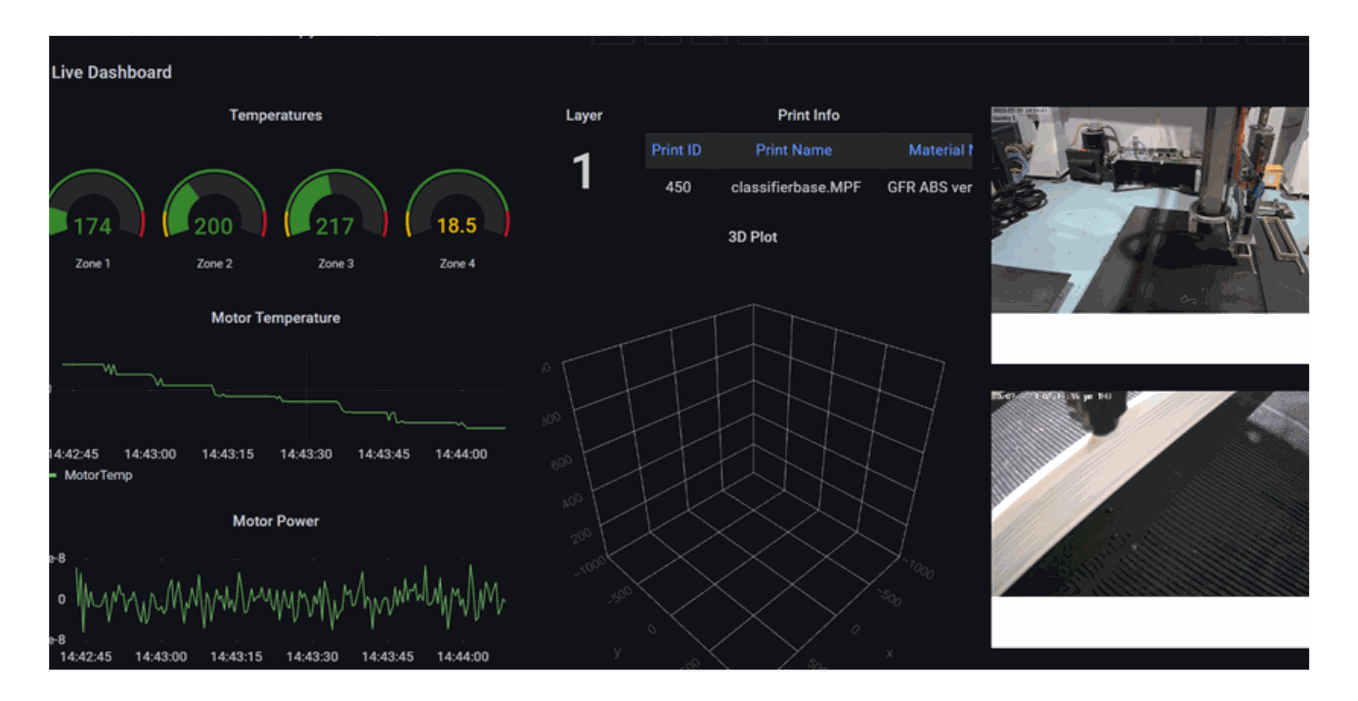

Industry 4.0 - VSF Dashboard

Industry 4.0 - VSF Dashboard

VSF Dashboard can be viewed from anywhere via a web browser and shows a complete real time picture of the print status and printing parameters.. This enables unmanned remote monitoring of the print ‘process. Very useful for long print runs.

VSF Dashboard can be viewed from anywhere via a web browser and shows a complete real time picture of the print status and printing parameters.. This enables unmanned remote monitoring of the print ‘process. Very useful for long print runs.

Industry 4.0 with Edge Device

Industry 4.0 with Edge Device

Allows users to view the print process via two or more IP cameras and to record print process data. Axis positions, CNC part program block numbers and process variables such as print speed, bead width are stored with time stamp. The data is stored on a Edge Device and enables retrieval, analysis, display, and replay. Data can also be extracted for external analysis.

Allows users to view the print process via two or more IP cameras and to record print process data. Axis positions, CNC part program block numbers and process variables such as print speed, bead width are stored with time stamp. The data is stored on a Edge Device and enables retrieval, analysis, display, and replay. Data can also be extracted for external analysis.

ROS Interface

ROS Interface

For VSF systems with SINUMERIK ONE, we offer an optional ROS interface, for transfer of real time data and motion commands between the SINUMERIK ONE and a ROS system.

This enables integration of robots and other devices with VSF. We supply a PCI card (CP1616) to mount in the customer’s supplied PC.

For VSF systems with SINUMERIK ONE, we offer an optional ROS interface, for transfer of real time data and motion commands between the SINUMERIK ONE and a ROS system.

This enables integration of robots and other devices with VSF. We supply a PCI card (CP1616) to mount in the customer’s supplied PC.

Want to know more?

Want to know more?