Concrete printed parts are heavy, and they take time to cure after 3D printing. In the simplest case parts are printed onto a concrete floor or fixed print table and then moved with an overhead crane or forklift. Where customers do not have an overhead crane an alternative is our mobile Print table:

Concrete printed parts are heavy, and they take time to cure after 3D printing. In the simplest case parts are printed onto a concrete floor or fixed print table and then moved with an overhead crane or forklift. Where customers do not have an overhead crane an alternative is our mobile Print table:

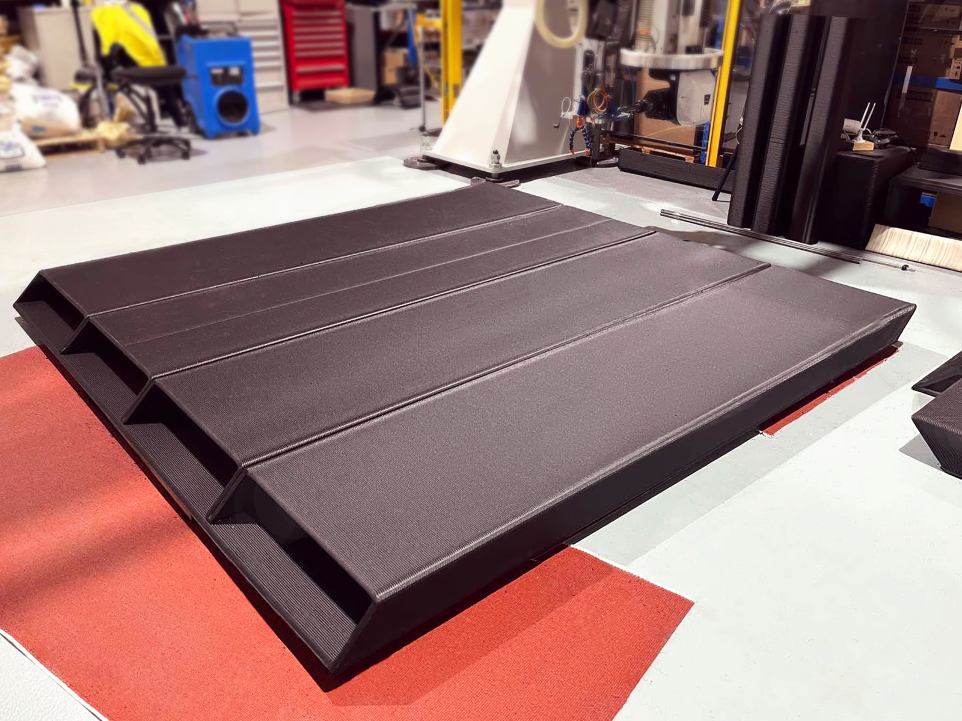

VSF Fixed Print Table

Steel plate mounted to a frame attached to the floor under the gantry. This gives a flat and level surface suitable for printing. Dimensions to match printer size.

VSF Fixed Print Table

Steel plate mounted to a frame attached to the floor under the gantry. This gives a flat and level surface suitable for printing. Dimensions to match printer size.

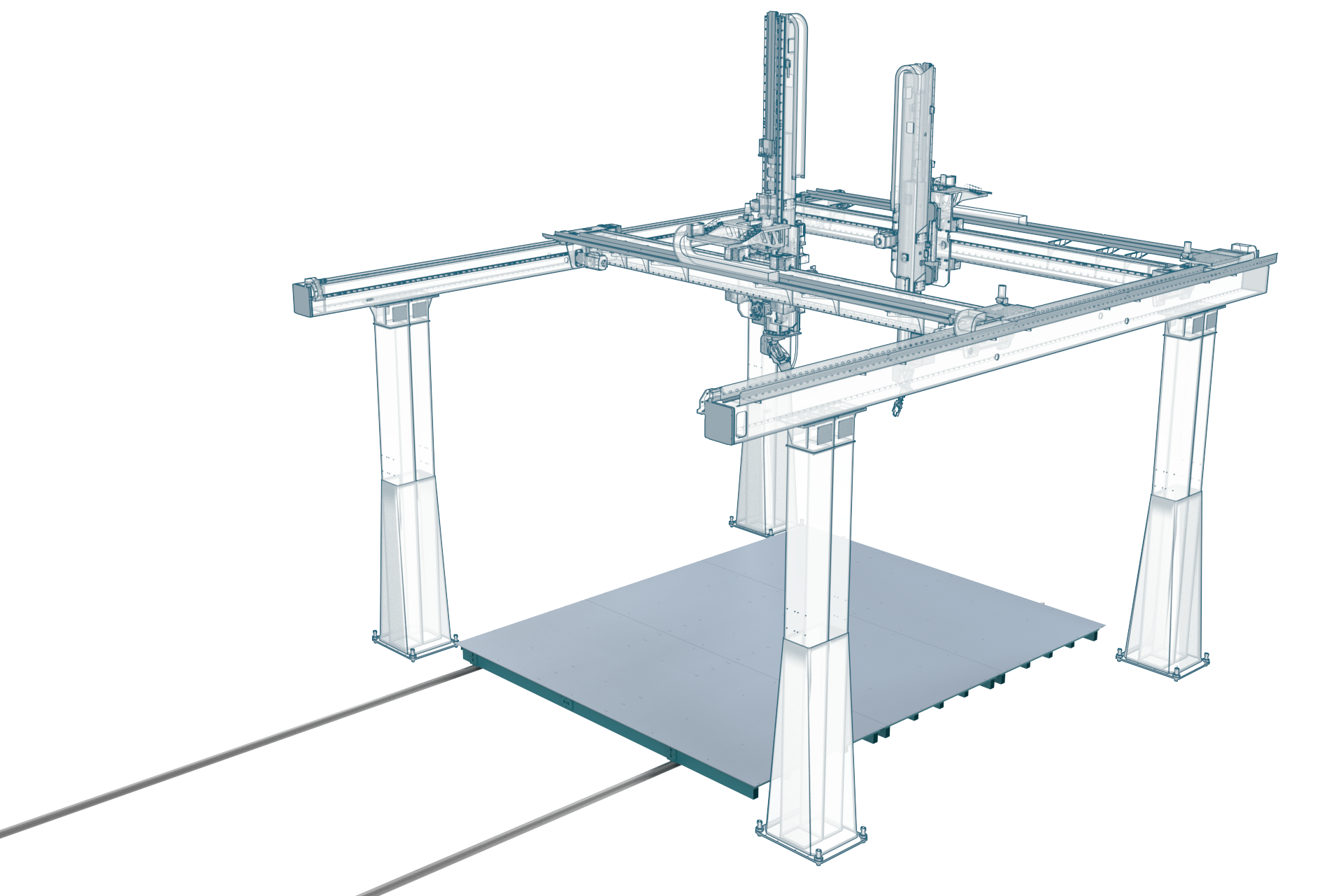

VSF Mobile Print Table

Our VSF mobile table is a powered unit which can drive itself on rails. These are concreted into the floor under the gantry and extending out of the print area where the part can be lifted off and the table retracted. Movement is enabled via a failsafe hold to run switch and safety bumpers are fitted front and back.

VSF Mobile Print Table

Our VSF mobile table is a powered unit which can drive itself on rails. These are concreted into the floor under the gantry and extending out of the print area where the part can be lifted off and the table retracted. Movement is enabled via a failsafe hold to run switch and safety bumpers are fitted front and back.

Specification:

· Max Printed part weight 20 Tonnes

· Print Bed Dimensions 7.6m x 3.8m

· Max Table height above Floor 300 mm

· Print Bed Mass 4500 Kg

· Automation Powered driven rail wheels via motor/gearbox.

· Rollers 8 sets each with 4 tones bearing load capacity.

This robust steel construction ensures efficient and reliable handling of large 3D printed parts.

Specification:

· Max Printed part weight 20 Tonnes

· Print Bed Dimensions 7.6m x 3.8m

· Max Table height above Floor 300 mm

· Print Bed Mass 4500 Kg

· Automation Powered driven rail wheels via motor/gearbox.

· Rollers 8 sets each with 4 tones bearing load capacity.

This robust steel construction ensures efficient and reliable handling of large 3D printed parts.

Key advantages of the rail based Print Table system

Keeps the mobile table localised which minimises potential to hit other objects or people.

Minimises potential to hit other objects or people.

Moves with relatively low friction so energy efficient.

Spread the load sufficiently over a longer area.

Low profile table for maximum print height.

Cost Effective Automated Solution.

Key advantages of the rail based Print Table system

Keeps the mobile table localised which minimises potential to hit other objects or people.

Minimises potential to hit other objects or people.

Moves with relatively low friction so energy efficient.

Spread the load sufficiently over a longer area.

Low profile table for maximum print height.

Cost Effective Automated Solution.

Want to know more?